Product Description

Product DescriptionOver the years, we have been designing, developing and manufacturing various inspection equipment such as in-circuit tester · function tester together with major inspection equipment manufacturers.We make use of our technology and experience to meet various customer's requests.

■The JTAG boundary test function was installed in the in-circuit tester THOMAS-NT.

■You can easily check the connection of JTAG compliant devices.

■Optionally supports FPGA configuration with JTAG.

| JTAG | |

|---|---|

| JTAG boundary test | Standard equipment |

| FPGA configuration | Option(TBD) |

| In-Circuit Test | ||

|---|---|---|

| Total number of corresponding PIN |

Standard 200 Pin up to 1000 Pin | |

| Number of test steps | Unlimited | |

| Guarding | Up to 5 points Maximum applied current 20mA | |

| Self-diagnosis function | Standard equipment | |

| Measurement time | Short / open test | 1pin/1ms~ |

| Component test | 0.75ms~ | |

| Main inspection items | Short / open test | All pins brute force method |

| Electrical resistance | 0.1Ω~40.00MΩ | |

| Condenser | 10.00pF~40.00mF | |

| Coil | 10.00μH~40.00H | |

| Diode | 0.01V~9.99V | |

| Photo coupler | 0.001V~4.00V | |

| Current measurement | 100nA~10mA | |

| JTAG | |

|---|---|

| OS | Windows7 |

| CPU | Intel Pentium D / Celeron D or higher |

| Display | TFT 17 inch LCD (1280 × 1024) SXGA or more required |

| Printer | Compact USB thermal printer (Thermal paper type) |

| Power source used | AC100V~240V±10% Single-phase(50Hz/60Hz) |

| Air | 0.5~1.0Mpa |

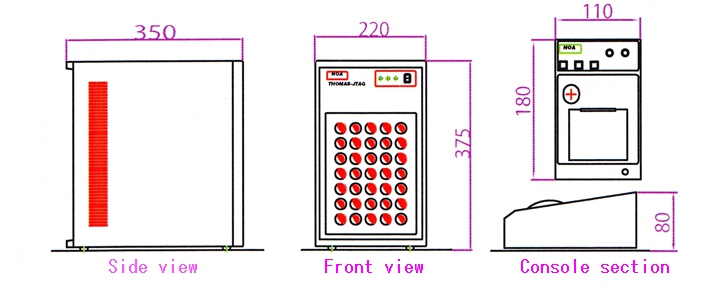

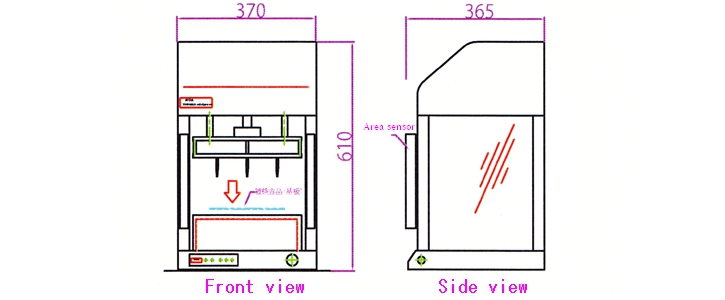

| Power consumption, Gross weight |

120VA,Body:14kg,Press:26kg |

| Operating environment condition |

Temperature:10℃~30℃ Humidity:0%~80% |

| Measurable substrate dimensions |

(Measured according to customer's measurement object)THOMAS-Minipress 250mm×115mm |